Production technology

The production of high pressure metalcomposite cylinders includes the following steps:

- tubes incoming quality control

- cutting blanks for liners

- cleaning the inner surface of the blanks

- blank wash

- seaming of the liner

- control of the size and inner surface of the liner

- heat treatment and artificial aging procedure

- control of the mechanical characteristics of the liner material (mechanical testing laboratory)

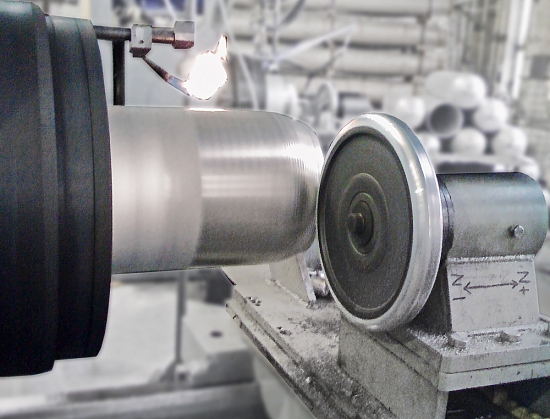

- liner neck turning

- liner size control

- liners pressure test

- transportation of a batch of liners to a separate division in Nizhny Novgorod

- liner incoming quality control

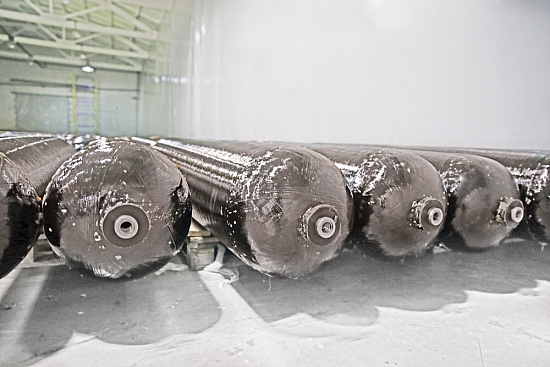

- winding of composite material

- furnace drying and polymerization

- autofretching, pressure test of the cylinders

- warehousing and transportation

Each batch of cylinders is protected by random testing, including:

- comulation cylinder life cycle testing

- cylinder selective pressure crash testing

- determination of the mechanical characteristics of the liner